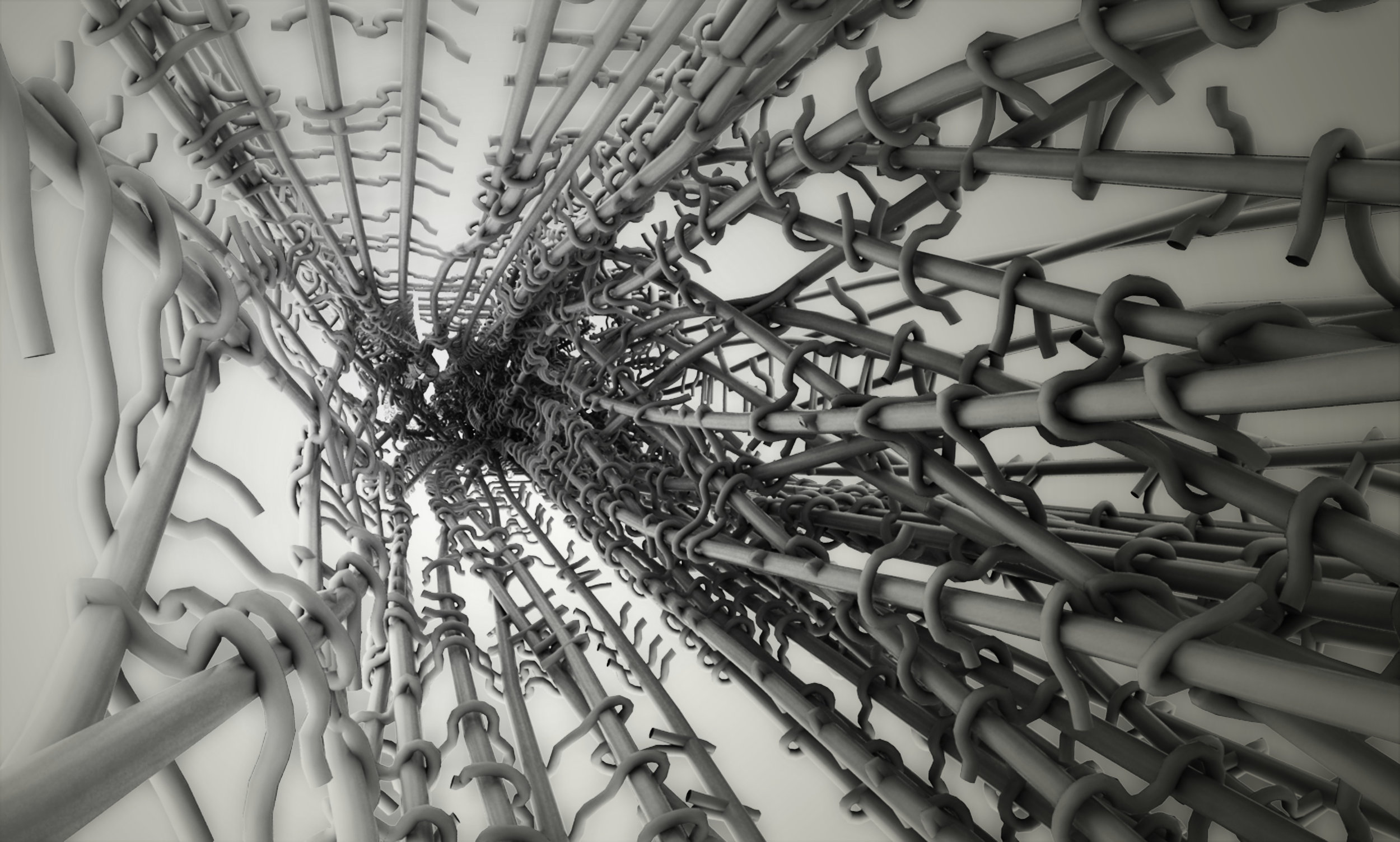

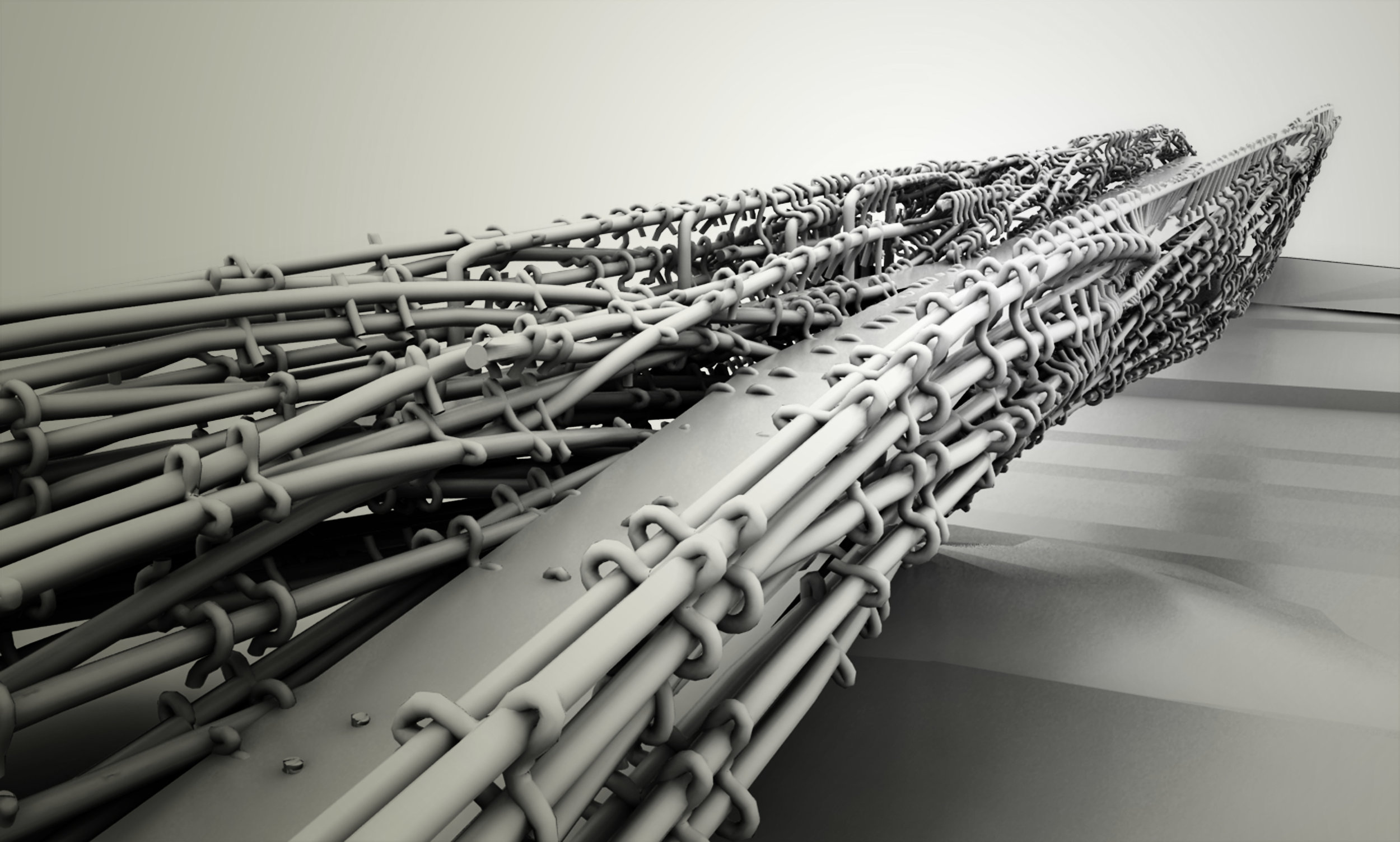

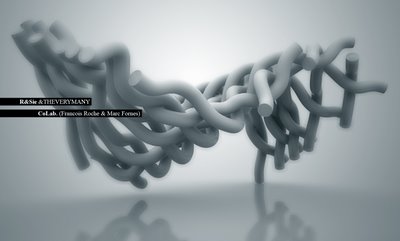

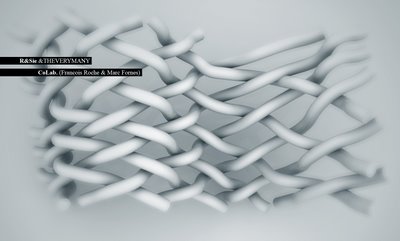

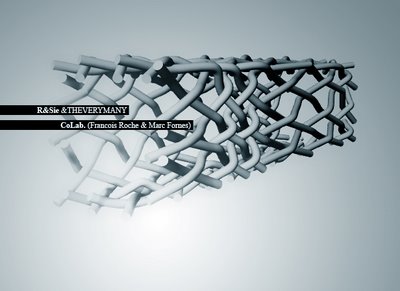

AGGRAPHS / ADAPTIVE CLIPS

developped with Francois Roche, R&Sie(N)

Project: Loophole, 2008 Architect: R&Sie(n), Paris Associated partner: Marc Fornes (on parametric clips). Dimensions: 60 m span Location: Cieszyn (Poland/Czech) Cost: 2 million €

All images & morphologies for the Aggraphs/Clips by Marc Fornes Computational protocols (Rhinoscript) for Aggraphs/Clips & 3D weaving by Marc Fornes

Both schemes presented bellow are part of many options developed in Rhinoscript for a system of adaptive Aggraphs/Clips onto a primary set of non uniform longitudinal structural members.

The option bellow (not final) was looking at an assembly of single type of rings with standard pipes (of custom length) --- a ring /steel pipes interface would have been needed in order to allow the rings to follow the direction of the weave for perfect snapping.

++++++++++++++++++++++++++++++++++++++++++++++++++++++++

++++++++++++++++++++++++++++++++++++++++++++++++++++++++

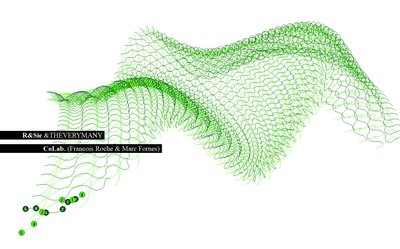

+++ 3D weaving system

Weaving protocols are quite straight forward in terms of computation as extremely explicit by nature: basically a set of procedure telling up/down/up/down based on a specific period or pattern.

Though in the specific case of this bridge - one had to weave through a given primary direction (or loom) which is non linear - basically a set of "randomly" weaved curves not following one overall set of rules - therefore as no under laying order or "grid" one can't expect within the loops to understand its front, back, left & right neighbors, and therefore if those are up or down... no global sequence of weave can't be applied...

Option presented - first attempt for sets of local agraffes/clips searching for their path.

(Obviously at that stageof the design process - no need to run any clash procedure to understand membrure/rib's integrity limit or structural weakness - but enough though to validate the hypothesis of scenario and its possible effect...)

++++++++++++++++++++++++++++++++++++++++++++++++++++++++

++++++++++++++++++++++++++++++++++++++++++++++++++++++++

Side track notes:

WEAVING (from wikipedia.org)

WEAVING is the textile art in which two distinct sets of yarns or threads, called the warp and the filling or weft (older woof), are interlaced with each other to form a fabric or cloth. The warp threads run lengthways of the piece of cloth, and the weft runs across from side to side. Cloth is woven on a loom, a device for holding the warp threads in place while the filling threads are woven through them. Weft is an old English word meaning "that which is woven".

The manner in which the warp and filling threads interlace with each other is known as the weave. The three basic weaves are plain weave, satin weave, and twill, and the majority of woven products are created with one of these weaves.

Woven cloth can be plain (in one color or a simple pattern), or it can be woven in decorative or artistic designs, including tapestries. Fabric in which the warp and/or weft is tie-dyed before weaving is called ikat. Fabric decorated using a wax resist method is called batik.

The ancient art of handweaving, along with hand spinning, remains a popular craft. The majority of commercial fabrics, in the West, are woven on computer-controlled Jacquard looms. In the past, simpler fabrics were woven on dobby looms and the Jacquard harness adaptation was reserved for more complex patterns. Some believe the efficiency of the Jacquard loom, and the Jacquard weaving process makes it more economical for mills to use them to weave all of their fabrics, regardless of the complexity of the design.

WEAVING / PROCESS

In general, weaving involves the interlacing of two sets of threads at right angles to each other: the warp and the weft. The warp are held taut and in parallel order, typically by means of a loom, though some forms of weaving may use other methods. The loom is warped (or dressed) with the warp threads passing through heddles on two or more harnesses. The warp threads are moved up or down by the harnesses creating a space called the shed. The weft thread is wound onto spools called bobbins. The bobbins are placed in a shuttle which carries the weft thread through the shed. The raising/lowering sequence of warp threads gives rise to many possible weave structures from the simplest plain weave (also called tabby), through twills and satins to complex computer-generated interlacings.

Both warp and weft can be visible in the final product. By spacing the warp more closely, it can completely cover the weft that binds it, giving a warpfaced textile such as rep weave. Conversely, if the warp is spread out, the weft can slide down and completely cover the warp, giving a weftfaced textile, such as a tapestry or a Kilim rug. There are a variety of loom styles for hand weaving and tapestry. In tapestry, the image is created by placing weft only in certain warp areas, rather than across the entire warp width.