first self-supported carbon fiber shellS applied to architecture.

POP UP STORE FOR A Collaboration with Louis Vuitton & Yayoi KUSAMA

Selfridges, London, UK (2012)

Design / Development / Innovation : MARC FORNES / THEVERYMANY

With composite - and the world of large one off structures (racing boats,...) - Molds are one of the largest expense (up to 1/3 of the cost) as they combine two different functions: Form (structure) and Finish (durability, aesthetic).

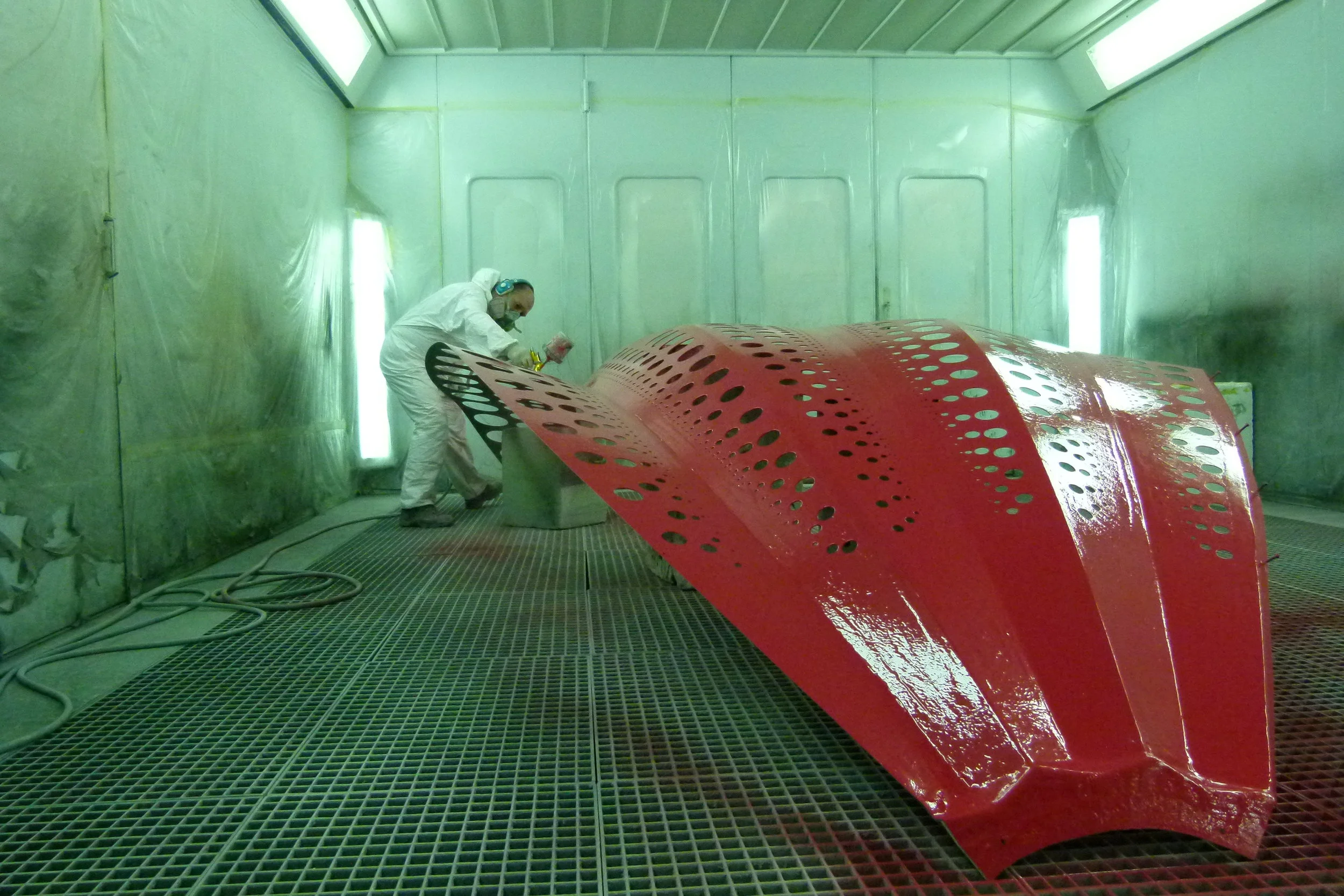

The transfer of technology and application of Carbon Fiber composite to Architecture was here made economically efficient with a simple hypothesis: avoiding molds through a dichotomy between Form (temporary scaffold) and Finish (glass quality support when infused):

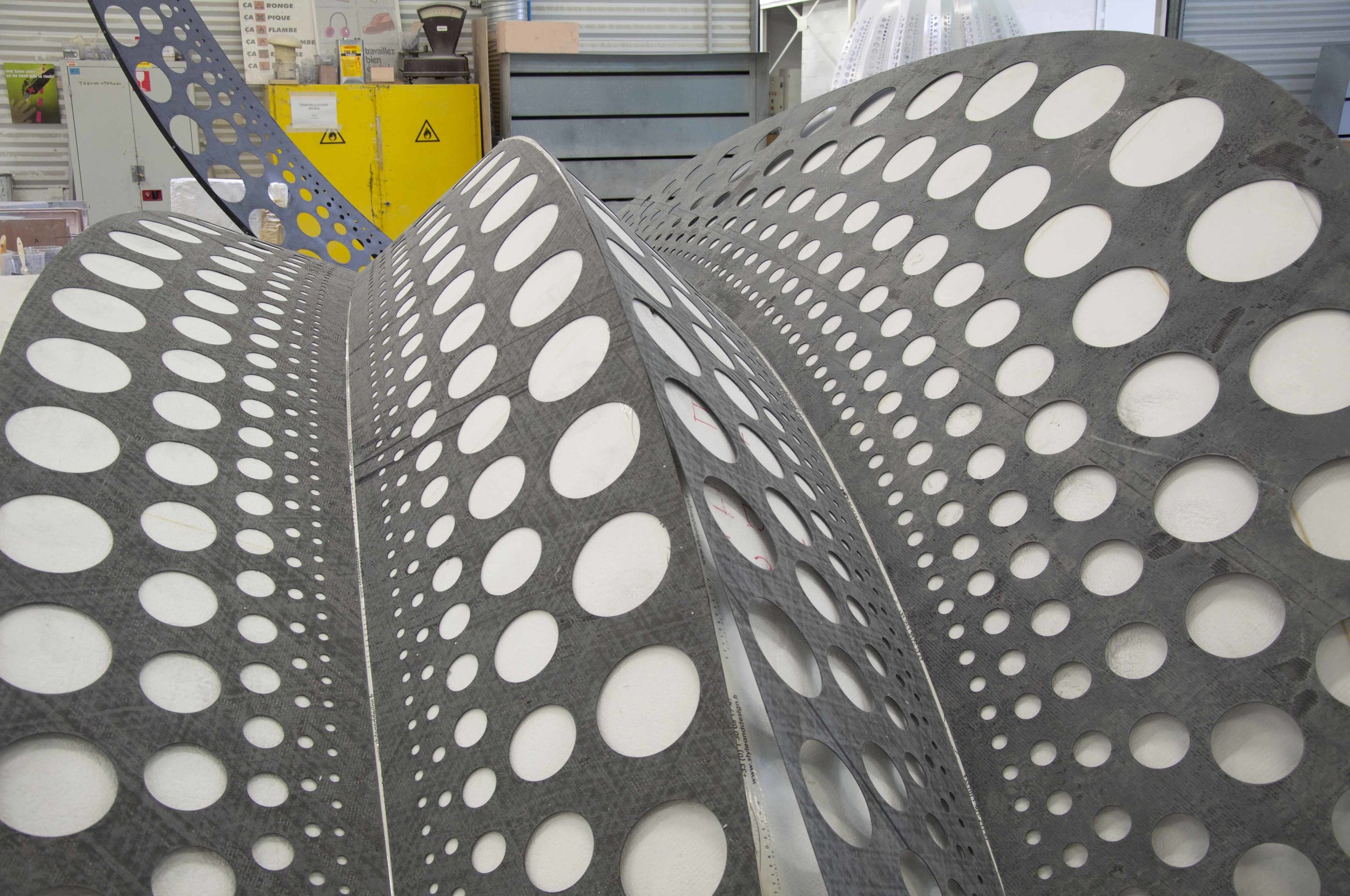

- large slices of carbon were produced via vacum infusion on 7m long tables. Tables are extremely cheap and can provide perfect glass surface finish.

- low density foam was CNC miled (extremely fast to machine) fast) to shap and was used as temporary (yet accurate) 3 dimensional scaffold that did not required any high end glossy smooth finish.

The carbon fiber slices were water jet cut to their templates, recombined on their 3D scaffolds and bonded together at the crease to shape large panels (able to fit through the doors of Selfridges. Within the bond at the crease was also hosting all sorts of cabling (network, security camera, lighting,...).