Style PORSCHE x MARC FORNES

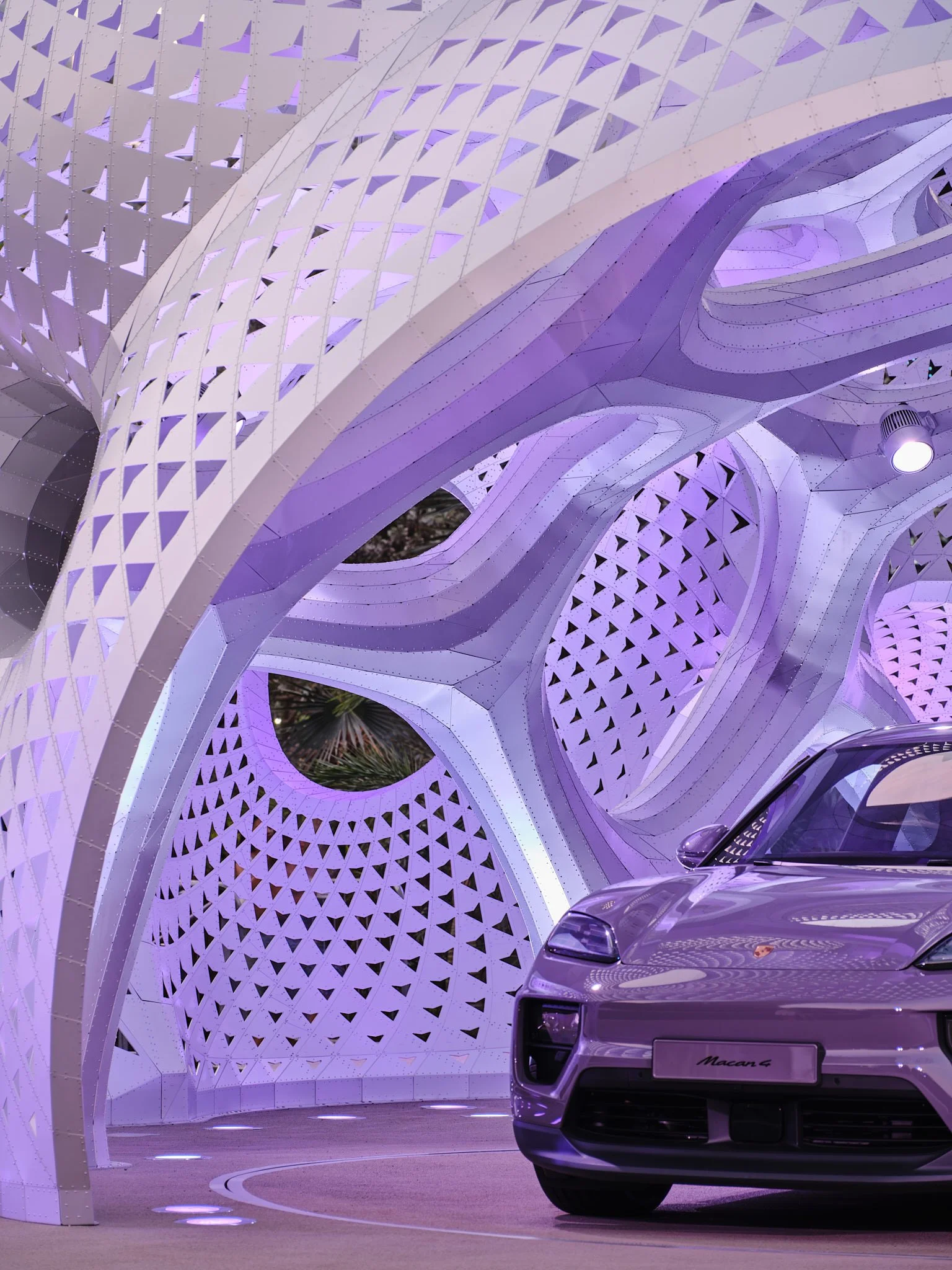

“ MY TWO CARS GARAGE ”

WORLD PREMIERE OF THE NEW ALL-ELECTRIC PORSCHE MACAN | Singapore

Style Porsche x Marc Fornes - Episode 1 - The Soul

Style Porsche x Marc Fornes - Episod 2 - The Artist

Style Porsche x Marc Fornes - Episode 3 - The Mission

Style Porsche x Marc Fornes - Episode 4 - The Process

Photos above from Porsche Newsroom (https://newsroom.porsche.com/): Oliver Blume (CEO of Porsche and Volkswagen Group), Michael Mauer (Vice President Style Porsche) and Marc Fornes (THEVERYMANY).

“My two cars garage”

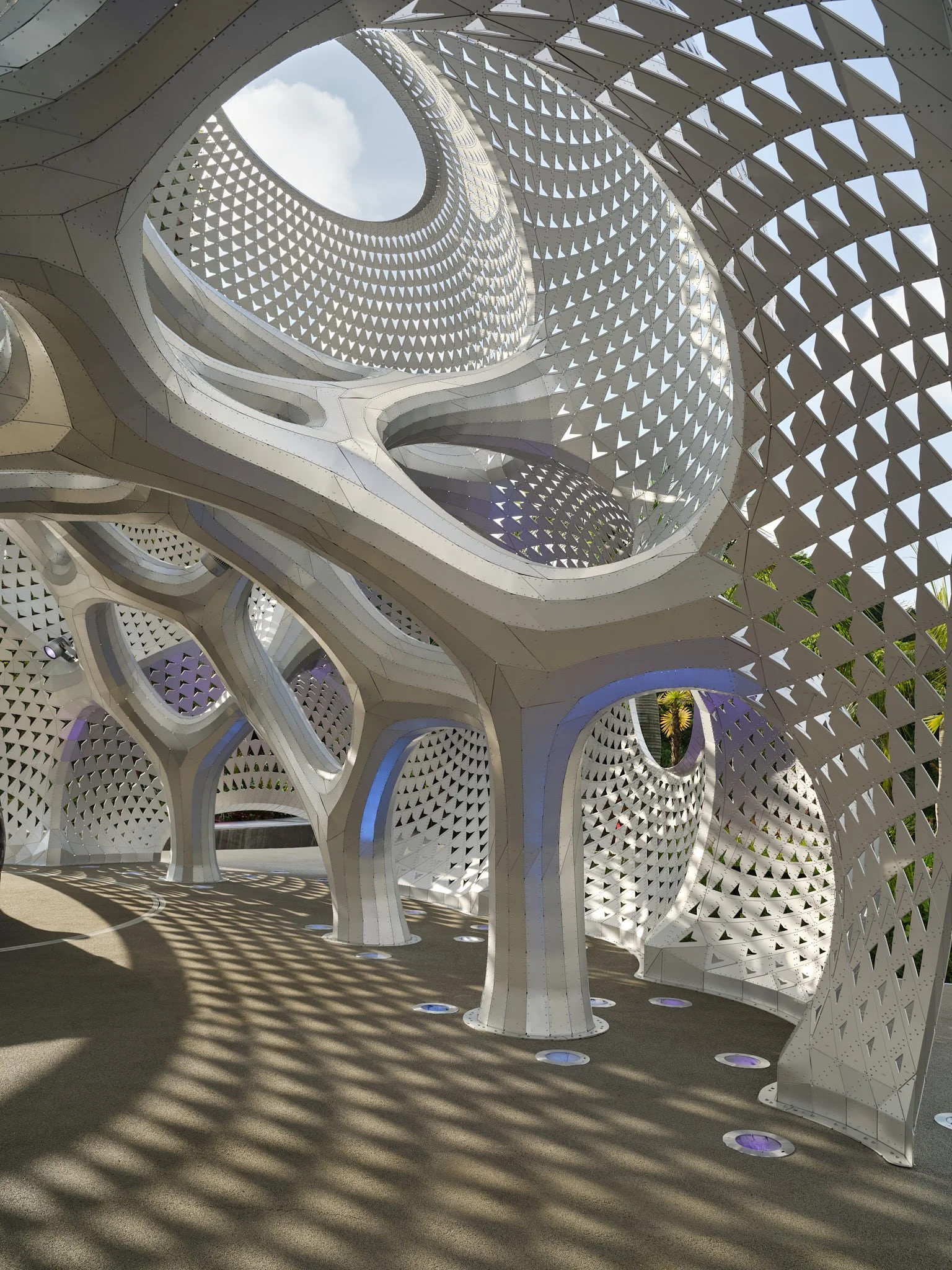

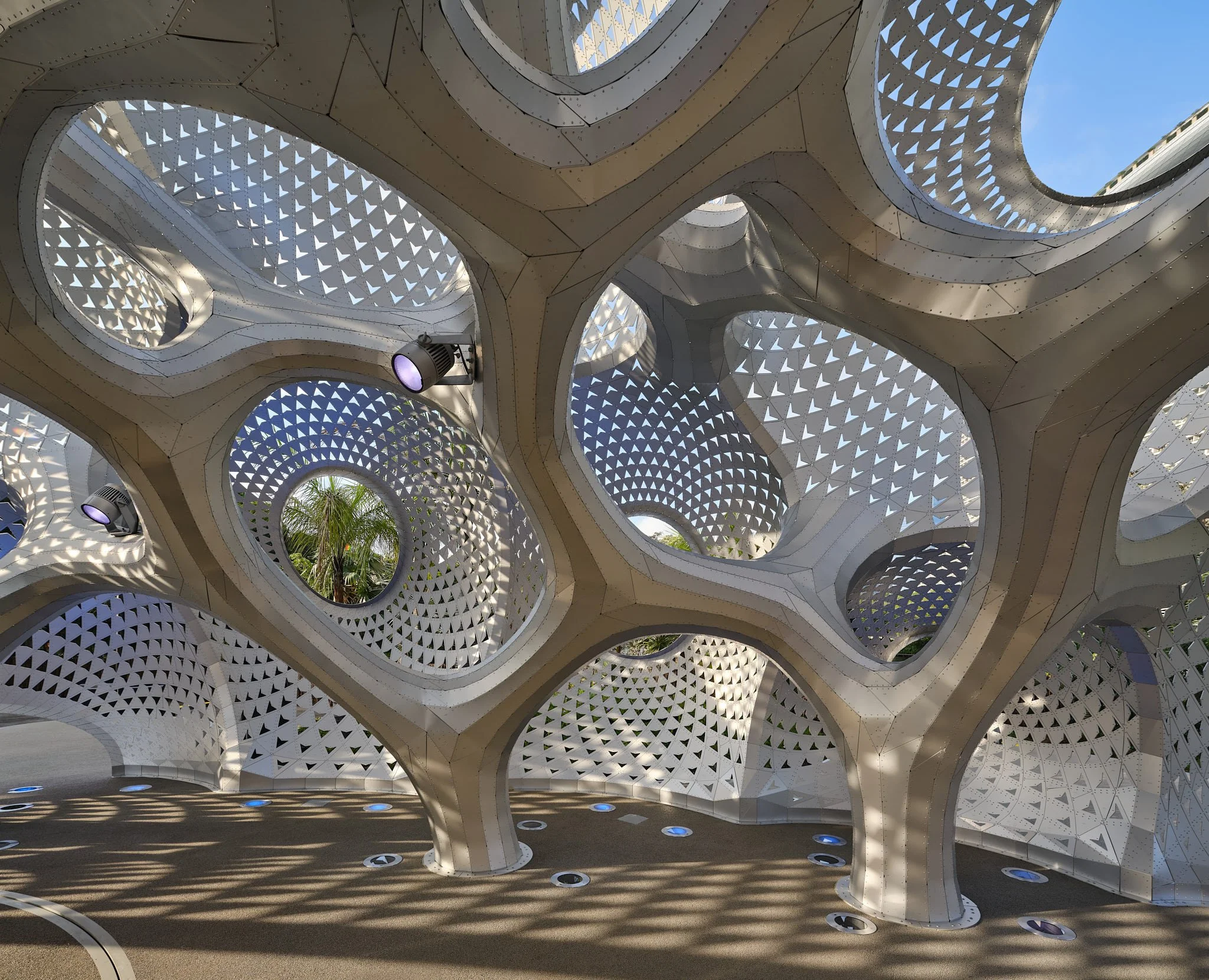

Ultra-thin, Self-supported, Aluminum Shell Structure

Commissioned by PORSCHE AG.

Architecture, Design and Computation by MARC FORNES / THEVERYMANY.

Location: Garden by the Bay, Singapore

Dimensions: L: 13.3m X W: 10.8m x H: 7m

Material: 1.5mm Aluminum

Linear Cut Distance: 26km

Number of Parts: 6,380

Number of Rivets: 202,203

“My two cars garage” is an ultra-thin lightweight shell structure designed as an immersive experience for the world premiere of the new all-electric Porsche Macan in Singapore.

The project is a collaboration between Michael Mauer (Style Porsche) and Marc Fornes (THEVERYMANY). Beyond a shared design sensibility and aesthetic, both designers have a strong interest in performance-driven design. They each approach their work guided by key principles:

Michael Mauer articulates his design process through “Focus, Purpose and Tension”

Marc Fornes emphasizes Essentialism (what you see is all there is, yet it is so much more), Specificity (each parts is unique, with a specific position and purpose), and Frozen Tension (the structure’s strength comes from its geometry, not its material).

Beyond the Art of Engineering nourished and developed in their respective studios, both designers strive to create uniques unique moments, memorable experiences and what they describe as Machines for Dreams.

The aluminum structure is Marc Fornes’s interpretation of a two-car garage. It is a single surface, shaping multiple elements into a unified system:

The Car. The Porsche Macan is the central focus of the structure. Its launch event is the main program. While the structure is initially designed as a display /surrounding environment for the car, its designed can host and display up to two cars, and offer the possibility for a dynamic reveal with the car driving through the structure.

The Structural Network. The surface, under high tension, shapes tubular profiles and connected elements. These not only help sustaining high wind-loads but also create a striking visual backdrop for the cars.

The Domes. Past the Network, the surface opens up into a series of inflated domes. Here domes are generated to optimize and provide the largest volume possible, using the least amount of surface while constraining their radius to be able to sustain horizontal wind loads.

The Openings. Emerging from a discussion between Michael and Marc in Weissach, the openings are directly inspired from the 3D texture of of plastic trims on the inside and outside of the new Porsche Macan. Being submitted to an intense schedule of production, the surface had to be made from non-processed 2D elements (no 3D texture). Therefore the openings reproduce a similar effect then walking along those trims, mimicking the changing highlights onto the original studded Porsche texture, triangles faiding into chevrons. Beyond the referential to the car, the motif of openings creates dynamic shadow motifs during the day, while radiating rays of lights in the evening.

Driven by Performance, the ultra-thin doubly curved surface is constructed from a laminated “multiply” system, a signature of THEVERYMANY referred to as “Fornes Strutural Strips”. It consists of two layers of thin aluminum linear elements, arranged in opposite directions and mechanical connected. Each piece is initially flat, but when the sum of them starts to take their final geometry by step by step connecting each one to the next, going from wobly to extremely rigid geometry once locked in their final geometry. Such an assembly process is refered to as “walking” assembly.

Some key numbers:

The aluminum is 1.5mm thick.

The structure stands 7m tall.

It requires over 26km of laser cutting to create the 6,380 unique parts that form this 3D puzzle.

More than just numbers and optimizations, the structure provides an immersive environment, designed to spark curiosity and imagination in its visitors.

Photo: doublespace

Photo: doublespace

Photos above: doublespace