n|Strip

Galerie Synesthesie, Paris | March/April2010

Design & computation: MARC FORNES / THEVERYMANY™ ©2010

Co-production: Galerie Synesthesie (Paris) with Galerie Roger Tator (Lyon)

THEVERYMANY™ | (n)perical realities

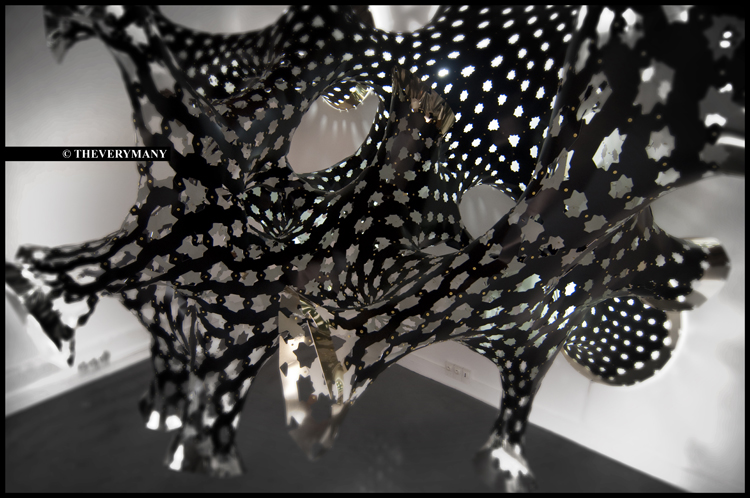

Too many is much too slow! - many has many advantages - yes - yet numerous is unfortunately not always realistic when one has to be assemble within our physical paradigm. Computation syntax made it too "easy" to develop and describe geometrically massive series of similar components/parts: 5000, 10000, even 30000 parts all unique are now "common" - yet such systems are also becoming larger challenges - even nightmares - of logistic, production schedules, assembly time, labor, favors, etc... even as fast as one part assembled per minute I still let you to do the math for the overall. Assembly is currently one the major issue THEVERYMANY™ is experiencing while on its quest of building larger and larger distributed / aggregate systems.

I originally thought by increasing the level of information on each part - beyond the classical ego centric information of its name (such as the one of its neighbors,etc...) - might help to reduce back and forth between screen and piles of components sorted on the floor - though it quickly came down to the economics of time of CNC machining. I then questioned/restricted the number of possible neighbors. Etc...

Design problem: can one address the question of assembly efficiency through geometry?

While on previous installation many different ways of surfaces tessellation were investigated - from applied onto open Nurbs surfaces to closed Polysurfaces / Breps - from arrays of components to non linear search strategies - could a going back to a simpler component such as a linear stripe morphology yet developable (therefore still able to be unrolled) and longer (therefore much less of them required!) still provide the same intricacy and continuity of surface then the sum of single components though being assembled much faster?

A complex morphology as a non-linear substrate to test linear search cases:

The overall geometrical strategies developed here is a mix between: a network ( distributed system as non-linear study case to test its descriptive strategies) and a tree (hierarchical branching system to highlight direction within the room)

“n|Strip” as sum of its parts: - 1 overall morphology - 3 people travelling from NYC with: - 3 boxes 18’*18’*24’ - 1 snowboard bag - 501 aluminum stripes, - 79 individual panels, - 580 annotations - 6866 rivets holes - 9.5 sheets 4*8 of black/white - 1 sheet of gold - 2 pistolets a rivets - 3 days to assemble - 13 people helped for the assembly

3 People luggage...

Opening...

Missing the (now usual!) notice from the US customs saying they opened the box...

Collective behaviours...

Before / should be...

Battle FIELD...

Reverse...

2 of many...

Part made of parts...

Analogy?

Edges...

Through...

Within...

Underneath...

25 March - 08 April 2010

Espace Synesthésie, Paris 15 rue Denfert-Rochereau 93200 Saint-Denis 01 40 10 80 78

Press contact: Marie-Charlotte Gain-Hautbois mchautbois@synesthesie.com T./F. : +33 (1) 40 10 80 78